| |

|

[Maximum rotational speed 21,500rpm]

Driven by inverter, 0.8kW totally-enclosed high frequency customized motor is equipped. Actural rotational speed measured by rotational-speed-sensor is displayed on the screen. Rotational speed is easy to control and stable.

|

[Best price]

With optimal manufacturing system, we are offering best price of these high performance machines. |

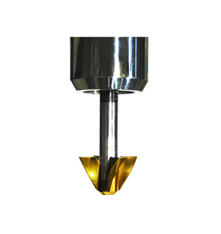

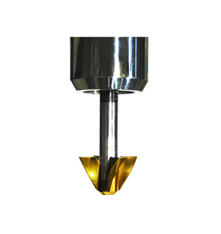

[Rotor / Screen]

The Rotors(R2, R4) and The Screens (S1.5-24, S2.0-24) are packed as accessory.

Examine each combination of the rotor and the screen to control particle's diameter, dispersion time, mixing heat and so on. |

[Clearance 0.2mm]

Clearance setting between the rotor and the screen is 0.2mm. You can check out the effect of clearance on dispersion by attaching optional screens which set up 0.5mm or 1.0mm clearance. |

[TiN coating (TiN-PVD)]

The Rotor/Screen is made of SUS316 and its surface is coated with TiN to improve resistance to erosion. As option parts, Stellite Rotor/Screen is available for high-abrasion- resistance-use such as ceramics dispersion. |

[CLEAMIX DISSOLVER]

Look at the picture on the left. R4 Rotor with no Screen is effective for mixture dissolution. Dispersion/Dissolution of matters such as aqueous high polymer (thickening agent) could have done in short time without converting matters into lower molecular weight polymer. |

[Alignment of the Rotor/Screen and Flow pattern ]

The Rotor/Screen moves up and down by an electric motor.

When mix/disperse matters in beaker, adjust the alignment of the Rotor/Screen where fluid doesn't engulf air .( Air bubbles reduces mixing/dispersing power. )

Fluid flows downward from fluid-surface into the Roter/Screen part. |

[Sanitary Design and Cleanability]

Under fluid part is smooth and small. It is easy to cleaning. Steam sterilization is supported. |

[Pressure and vacuum specification]

It can drive under pressurized condition (max 0.1MPa) or vacuum condition. Special LIP-seals are attached to seal-housing and to screen-holder. Special LIP-seal is easy to replace by special tool ( accessory ).Shaft-surface is coated with ceramics and it's high wear resistance. |

[Casing with jacket specification]

When The Rotor rotates extremely fast, mixing heat is generated. Mixing heat might be a problem for low temperature processing. Cleamix is equipped a casing-jacket to reduce or control that heat. |

[Safety Design]

The Rotor and The Rotor-shaft are covered by The Screen and The Casing.. All moving parts are untouchable while it's driving. (except Dissolver combination.) |

| |

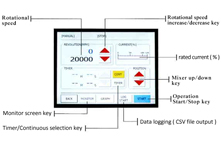

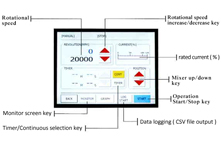

Features

Data logging: Save as CSV-file.

Programmable/Manual controller.

2 terminals for optional temperature-sensor (option).

2 terminals for optional pressure-sensor (option).

Liquid level meter (option). |

Specifications Specifications

|

| Type |

CLM-0.8S |

| Rotational speed |

21500 rpm ( maximum ) |

| Throughput |

50cc to 3,000cc |

| Motor |

0.8kW totally-enclosed high frequency customized motor |

| Power |

AC100V  30A 30A  50/60Hz 50/60Hz |

| Size |

Main body 355W*275D*630H

Controller 225W*359D*408H |

| Weight |

Main body 25kg

Controller 12kg |

| Material Finish |

Wetted parts SUS316(Buffing #400), Rotor / Screen SUS316 + TiN coating, Shaft SUS316 + Ceramics, PTFE, FKM

Non wetted parts SUS304 NBR, FKM, CS |

| Shaft seal |

Special lip seal |

| Operating conditions |

Pressure F.V to 0.1MPa

Temperature maximum 100 degrees Celsius

(Please contact us for Autoclave specifications) |

| clearance |

Rotor/Screen 0.2mm (0.5mm, 1.0mm by replacing optional screens) |

| Rotor |

R2 R4 R4 |

| Screen |

S1.5-24  S2.0-24 S2.0-24 |

| Elevator |

Electric motor type |

| Controller |

Touch-screen type controller |

| Accessories |

Protective cover for mixing section, Base rubber plate, Special 3 tools ( Stopper, Seal attach/detach jig, Rotor/Screen Holder/Seal Housing attach/detach tool ), Dissolver seal housing, Ground adaptor, Maintenance grease. |

|

Examples of CLEARMIX Application Examples of CLEARMIX Application

|

| Medicine |

Ointment, Suppository, Medicated cream, Injection solution, Barium Sulfate, Liposome, Eye-drops, etc. |

| Chemical agent |

Paint, Pigment, Dye, Ink, Magnetic paint, Adhesive material, Wax, Coating agent, Mold lubricant, Aromatic substance, Film, Ceramics, Liquid crystal, etc. |

| Food |

Aroma chemical, Coloring matter, Mayonnaise, Dairy products, Juice, Ketchup, Seasonings, etc. |

| Cosmetics |

Cream, Emulsion, Lip rouge, etc. |

| Toiletry |

Shampoo, Rinse, Conditioner, Hair care cream, Gel, etc. |

|

|

Laboratory Equipment

Laboratory Equipment

Manufacturing Machines

Manufacturing Machines

M-coil type Heat exchanger

M-coil type Heat exchanger Deaerator

Deaerator System Engineering

System Engineering

Other various machines

Other various machines

![]()

![]()

![]()